Advancements in Cobblestone Construction Methods

Budgeting and Expense ConsiderationsWhat are the benefits of using cobblestone in landscape architecture?

When embarking on a cobblestone construction project, it is essential to carefully consider the budget and expenses involved. The costs associated with cobblestone work can vary depending on factors such as the size of the project, the type of materials used, and any additional services required. It is crucial to conduct a thorough cost analysis to accurately estimate the expenses involved and ensure that the project stays within budget constraints. Planning ahead and accounting for all potential costs can help avoid financial setbacks and delays during the construction process.

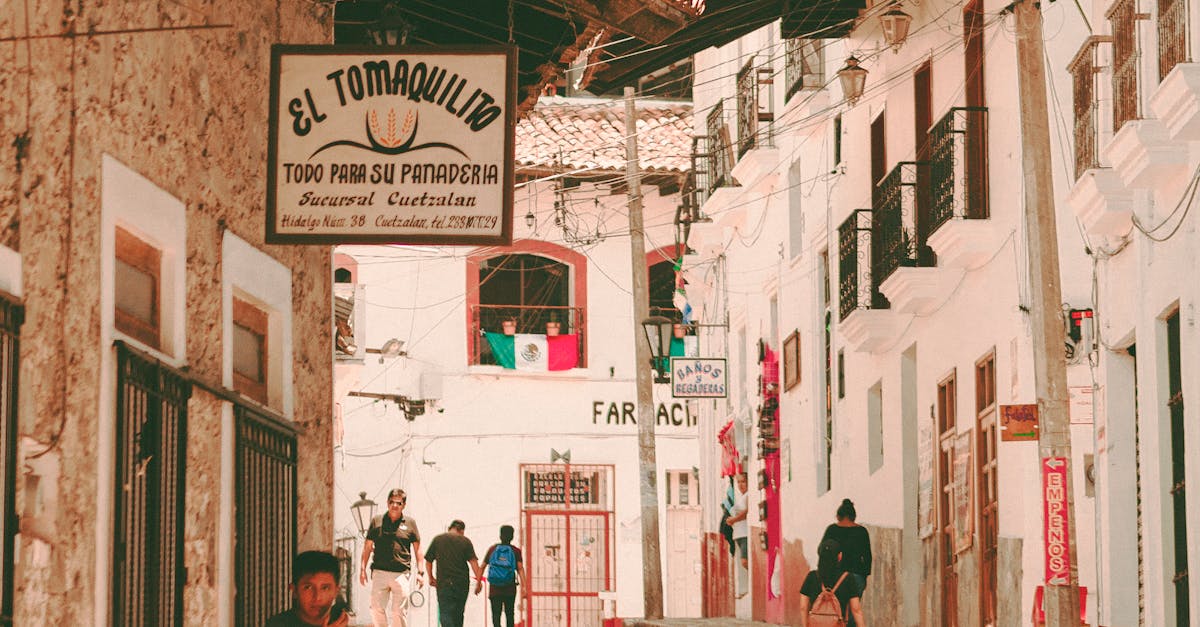

Cobblestone has a rich historical context in landscape architecture, dating back centuries to medieval times when it was predominantly used for practical purposes such as road construction iTo prevent slip and fall hazards on cobblestone surfaces, it is important to choose a textured cobblestone finish, apply an anti-slip sealant, and regularly clean and maintain the surface to remove any debris or moss buildup.n Europe. The use of cobblestone was a testament to the craftsmanship and dedication of builders to construct durable and long-lasting pathways that have stood the test of time. Over the years, cobblestone features have evolved from mere functional elements to revered artistic expressions that add character and charm to outdoor spaces.

In many cultures, cobblestone is symbolically linked to tradition, heritage, and a connection to the past. The enduring presence of cobblestone features in modern landscapes serves as a reminder of the craftsmanship and ingenuity of earlier generations. Additionally, cobblestone pathways and structures often symbolize longevity, strength, and resilience, reflecting the enduring spirit of communities that have embraced these enduring materials in their landscaping designs.Related LinksFAQS

The Role of Cobblestone in Traditional Building PracticesWhat are the benefits of using cobblestone in landscape architecture?Techniques for Laying Cobblestone in Historical ConstructionCobblestone is known for its durability, low maintenance requirements, and timeless aesthetic appeal, making it a popular choice for enhancing outdoor spaces.

Historic Developments in Cobblestone ConstructionHow can I maintain cobblestone landscapes to ensure longevity?

Traditional Cobblestone Construction PracticesRegular cleaning and resealing of cobblestone surfaces, addressing any issues with drainage, and conducting periodic inspections for damage can help prolong the lifespan of cobblestone features in landscape architecture.

The Impact of Cobblestone on Construction MethodsIn what ways can cobblestone be utilised in landscape design to create functional spaces?

Evolution of Cobblestone as a Building MaterialCobblestone can be used to delineate pathways, create outdoor seating areas, define garden borders, or even construct retaining walls, adding both practical functionality and visual interest to the landscape.

What is the cultural significance of cobblestone in landscaping?

Cobblestone's Influence on Architectural Material Selection

The Integration of Cobblestone in Contemporary Architectural Landscapes